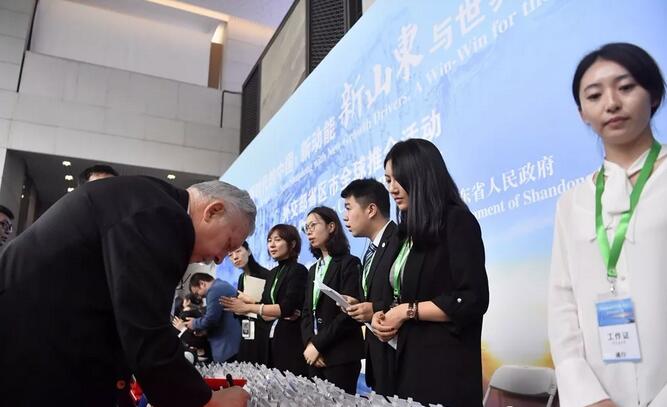

iqilu.com, reported on September 21 On September 20, over 500 persons assembled Blue Hall of the Ministry of Foreign Affairs, including over 240 ambassadors in China and diplomatic officials from 158 national and international organizations, more than 110 Chinese and foreign journalists, nearly 40 representatives of internationally renowned Chinese and foreign enterprises, representatives of relevant central and local departments. Shandong global promotion activities by the Ministry of Foreign Affairs themed "China in the New era: New Shandong with New Growth Drivers, A Win-win for the World" and held by Ministry of Foreign Affairs and People's Government of Shandong Province was held ceremoniously here. This is a meeting that Shandong Province, a coastal province with rich culture and history opens to the world.

Let's recall the wonderful moments together.

↓↓↓

Wonderful exhibition

↓↓↓

Attract eyes from the world! These Shandong "specialties" are placed on the "antique shelf" of the Ministry of Foreign Affairs

In the hall located at the 3rd floor of south building of the Ministry of Foreign Affairs, a wonderful Shandong tour exhibition with a concentration of 158,000 square kilometers attracted the eyes of many guests at home and abroad. Centipede kite with a dragon head, cloth tiger from Weifang, tin inlaying from Weihai, peach wood carving, eggshell black pottery cup from Feicheng and many other folk-art boutiques from Shandong are placed on the "antique shelf" of the Ministry of Foreign Affairs.

Centipede kite with a dragon head from Weifang

The centipede kite with a dragon head integrates the features of three-dimensional kites and string kites. It is made of hand-made three-dimensional faucets and many waist belts with dragons. Also, it is a representative work of Weifang kites and a wonderful flower in traditional Chinese folk culture. Its production process is complicated and difficult, which can be rated as the highest class in the world.

Tin inlaying from Weihai

Royal blue harmonious reading disk, and manual tin sheet drawing from Lanjun. . . . . . Tin inlaying from Weihai becomes the "New favorite" of the "Blue Hall".

Tin inlaying technique from Weihai has had a history of more than 1 hundred years, and it origins in the late years of Guangxu emperor of Qing Dynasty. The tin laying manufacture is very complex, and it has to pass through dozens of processes such as smelting, forging, carving, inlaying, polishing and splicing. The tin laying tea set is manufactured via smelting, casting, forging, carving, welding tin alloy into a variety of patterns to be inlaid in Shandong Boshan Camellia set afterwards, and finally to be polished into a delicate and beautiful practical art. The inlaying position of the tea set is exquisite, and the tin pattern is beautiful. For example, the pattern is often inlaid in the spout, the body of the pot, the lid of the pot, and the neck of the pot. Most of patterns on the lid of the pot are five bats surrounding a Chinese character "Longevity" and magpie on the trees. The gas holes in the middle of pot lid are specially cast by using copper coin of Guangxu Emperor. Most of patters of pot body are black dragon making fun with fire pearl, dragon and phoenix, pine and crane and so on.

Peach wood carving

"Peach wood carving from Feicheng" origins in the ancient "Taofu" from BC 26th century, formed in Sui and Tang dynasty, developed in Song Dynasty and entered the peak stage to the dynasties of Ming and Qing. "Peach wood carving from Feicheng" technique has its distinct style. After inheritance for a thousand years generation by generation, the products have developed into more than 4000 varieties in 30 major series. In 2006, "Peach wood carving from Feicheng" folk-custom was listed on the first-batch intangible cultural heritage inventories in Shandong Province.

Boshan glaze

"Like pearl and agate green, and a piece of scenery of amber and glaze".

The Boshan glaze exhibited at this time is jade green glaze ancient pier bottle and a Danfeng ancient pier bottle. Owing to the limitations of technology and raw materials, workshops have only been set up in Beijing and Boshan since ancient times for conducting glaze production. Boshan glaze began mass production in the Tang Dynasty and took shape in the Ming Dynasty.

Glass thermoforming is the most important traditional production process of Boshan glaze. After the craftsmen melt the glaze raw materials in a temperature of more than thousand degrees of high temperature, they use various tools to heat-process them by blowing, stretching, and kneading techniques. Via dozens of processes, various vases, flower balls, beasts are manufactured, which reflects "craftsmen spirit" in the best. Because of the special nature of the glaze, the timing of the liquid to solid finished product is instant, so the craftsmen need to race against time and complete the glazing shaping in a short period of time.

Black pottery from Dezhou

With drilled vases and eggshell retainer cup, the black pottery from Dezhou is vigorous and solemn.

The history of black pottery in Dezhou can date back to Dawenkou – Longshan culture, more than 4000 years before present. The ancient ancestors adored black, and the eggshell pottery in the black pottery was the highest-regulated ritual objects at that point. Dezhou Black Pottery chooses the unique red plaster on both sides of the Beijing-Hangzhou Grand Canal as the raw material. The texture of this earth is pure and delicate with high soil density. It will not be glazed after being formed by traditional manual wheel. During the process of drying the blank, it is calendered and engraved. After sintering under high temperature, the kiln is sealed to conduct carburizing treatment with burnt smoke. The fired pottery is black and clear like gold and is also solid and dignified; Rap it like jasmine, and it brings people a sense of "Black gold and jade". "Beautiful mountains and water, and jade comes from Kungang" and "Texture like iron and smoothness like jade", and so many words from men of letters can let people image art magic of black pottery.

Cloth tiger from Weifang

Happy tiger, big mansion with tiger, lion rolling big-leaf hydrangea and cloth tiger from Weifang exhibited show distinct folk culture of Shandong.

During the Han people's prosperity of the thousand’s years, tiger and dragon have built a national totem by virtue of their mighty and holy. The dragon is the symbol of the emperor and holy, and the tiger goes deep into the folk and becomes the spiritual ballast of the people. In Weifang, cloth tiger is the main form for craftsmen to manufacture cloth toys since ancient times. Up to now, tiger cap, tiger shoes, tiger pillow can be commonly seen in people's homes. The overall image of cloth tiger from Weifang is rather cute, and is suitable for children for play and can also be loved by ordinary people, which is relevant to the atmosphere of dense Confusion culture in Shandong Province.

During the exhibition, "the treasure of our country" manufactured by Shandong attracts the attendants to visit in a crowd.

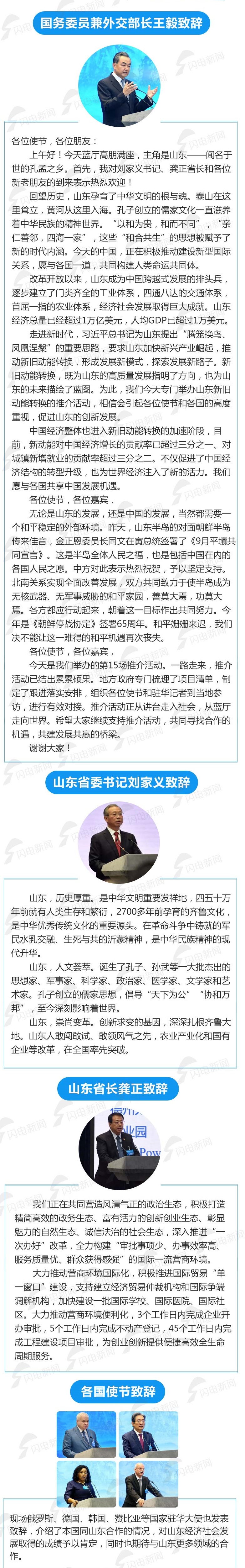

Renaissance was manufactured in Qingdao. It creates the highest speed during high-speed train operation test

The "Renaissance" produced by CRRC (Qingdao) creates the highest speed during high-speed train operation test. On September 21, 2017, the "Renaissance" EMU researched and manufactured by CRRC Qingdao Sifang Co., Ltd. realized commercial operation with the speed of 350 kilometers per hour on the Beijing-Shanghai express railway, which makes that our country becomes the country with the fastest speed during express railway commercial operation in the world. This builds new benchmarking for the global express highway.

CRRC Qingdao Sifang Co., Ltd. is the core enterprise subordinate to CRRC limited liability company and the industrialization base of high-speed train in China, manufacturing plant of domestic subway, light rail vehicle as well as an important export base for rail transportation device products in our country.

The first high speed train with the speed of 200-250 kilometers per hour, the first high speed train with the speed of 300 kilometers per hour, the first high speed train with the designed speed of 380 kilometers per hour as well as the first "Renaissance" EMU train are all from CRRC Qingdao Sifang Co., Ltd. CRH380A creates the records of the first with the speed of 486.1 kilometers per hour during the world high speed train operation test. "Renaissance" EMU realized the commercial operation with the speed of 350 kilometers per hour, making that our country becomes the country with the fastest high-speed train commercial operation speed in the world. The success of "Renaissance" marks that the high-speed train technology in our country realized automation and standardization. In the meantime, no matter operation speed, or safety performance, comfort, or energy-saving and cost-reducing and other technical indicators, "Renaissance" is the second to none in the world.

Install "China Core" on the transmission! Guide the world by the products manufactured by Shandong

Shengrui Transmission, which is the world's first 8AT front-mounted front-drive transmission, obtained the first prize of National Science and Technology Progress Award. And it is one of the "Top Ten Transmissions in the World" and has set R&D centers in Germany and the United Kingdom and so on.

Shengrui Transmission mainly specializes in R&D and manufacturing of automobile automatic transmissions and heavy-duty diesel engine parts. Fourteen years ago, the newly established Shengrui Transmission also faced industry difficulties and its development was rather difficult. The turnaround began three years later. As of 2006, Weifang Shengrui has continuously invested RMB 0.9 billion within 10 years, and successfully developed the world's first front-mounted front-drive 8-speed automatic transmission (8AT) with completely independent intellectual property rights, which has filled the domestic blank and promoted the automobile industry of our country to stride forward "8 speed times" formally.

Up to December 2016, Shengrui Transmission has owned more than 500 patents of AT series automatic transmission and hybrid series automatic transmission, of which there are more than 80 invention patents. Shengrui 8AT invention patent also won the Chinese Patent Gold Award, and the 8AT assembly technical standard became the first batch of enterprise standard leaders in Shandong and it also participated in the formulation of a number of industry standards.

In 2016, the 8AT project won the first prize of National Science and Technology Progress Award and became the only national first prize won by the auto parts industry since the establishment of PRC.

15240 meters! "Bluewhale I" defines "Depth of ocean"

"Bluewhale I" is an ultra-deep-water double-drilling tower semi-submersible type drilling platform constructed by CIMC Raffles Marine Engineering Co., Ltd. In May 2017, "Bluewhale I" made a success in the initial trial acquisition of combustible ice in the area of the South Sea of our country, which becomes a "focus" around the world.

"Bluewhale I" is a drilling platform with independent intellectual property rights independently developed by CIMC Raffles. It has completed the general contracting construction from design to procurement, production, commissioning to final delivery, and successfully passed the certification of the China Petroleum Marine Project Safety Operation Management System, and it was named and delivered in Yantai on February 13, 2017.

Bluewhale I have created two "Top of the world" items, including the largest operation water depth of 3658 meters and the largest drilling depth of 15240 meters. CIMC Raffles has also undergone a major reform of the "Bluewhale I" process design, changing the construction mode of semi-submersible type drilling rigs with the 20000-ton "Taishan Crane" with the largest lifting capacity in the world. Just by this step, the delivery period of the semi-submersible type platform production process was resolved. It took only 9 months to design, which shortens the standard design cycle by 3 months.

Among the high-end equipment manufacturing industry, which is one of the strategic emerging industries, marine engineering equipment occupies an extremely important position. While Yantai CIMC Raffles is currently the only enterprise in China that can construct high-end marine equipment in batches by industrialization. It has built China's largest marine engineering equipment construction base and has become one of the few marine industrial enterprises with a semi-submersible platform, a self-elevating platform and a marine special ship series.

As one of the first 7 companies in China to enter the "white list" of the marine equipment enterprises of the Ministry of Industry and Information Technology, CIMC Raffles has delivered 36 pieces of various marine engineering equipment by accumulation, more than half of which are from international mainstream customers, and the 9 deep-water semi-submersible type drilling platforms that have been delivered account for 80% of the domestic market share.

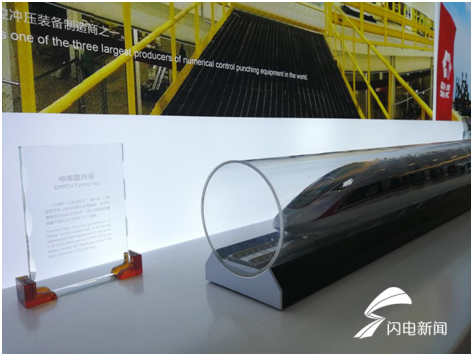

"Shandong Contribution" of large aircraft C919

On May 5, domestic big plane C919 successfully first took off in Shanghai Pudong International Airport, and this is a "China treasure" newly added and also a major milestone in the development history of China civil aircraft. On July 12, C919 air bus 102 planes took off from Shanghai Pudong International Airport, after flying for one hour and 46 minutes, it landed at Shandong Dongying Shengli Airport steadily. Thus, the initial remote ferry flight in the air was completed successfully.

To China, C919 is not only a main passenger plane, it means: CAAC will no longer depend on import from foreign countries and China's aircraft manufacturing really walks out of a road of independent development.

More proudly, many parts of homemade large aircraft C919 are "made in Shandong".

AVIC Research Institute for Special Structures of Aerionautical Composites undertook the design, development and manufacture of C919 aircraft radome. STAECO obtained the ARJ21-700 Aircraft Maintenance Permit issued by the Civil Aviation Administration of China on August 23, 2016; Shandong CAG Aviation Standard Parts Co., Ltd. produces rivets for C919 large passenger aircraft and ARJ21 aircraft; Oriental Bluesky Titanium Technology Co., Ltd. located in Yantai provides titanium alloy fasteners for C919 large passenger aircraft; National Supercomputer Jinan Center provides high-performance computing services for the C919 project.

C919 embodies not only the value of a large aircraft, but also the level of China's entire manufacturing industry.

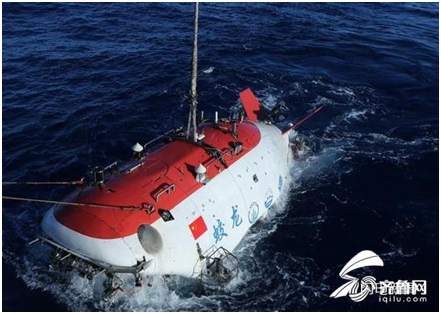

The fifth largest deep-sea technology support base in the world, Jiaolong, sailed out from here

The national deep-sea base, located in Aoshanwei Town, Jimo District, Qingdao City, Shandong Province, is the business operation support base for large-scale deep-sea equipment in China, and is also the fifth largest deep-sea technology support base in the world. "Jiaolong", the core carrier of the deep-sea scientific research in China, "settles" here. In the first ten-day period of January this year, the "research and development and application of the 'Jiaolong' manned submersible" project was awarded the First Prize of the National Science and Technology Progress Award.

The national deep sea base undertakes the research and development and testing of deep sea technology and equipment, carries out the operation and management of investigating ships, major equipment and others in the deep sea base, takes charge of the selection, training and management of submarine pilots and major equipment operators, organizes deep sea resource exploration, scientific investigation and environmental observation, and undertakes international cooperation and exchange in deep-sea scientific investigation, industrial transformation and service of deep-sea technological achievements, etc.

"Jiaolong" manned submersible is a self-designed and self-integrated manned submersible developed by China, which was listed as a major project of 863 Program in 2002. Its length, width and height are 8.2m, 3.0m and 3.4m, respectively, with 22 tons in air weights, 240kg in maximum load, 2 knots in maximum speed, 1 knot in cruising speed and 7000 meters in maximum working design depth.

On August 18, 2009, the first sea test of " Jiaolong" took the first step of China's manned deep dive with its first dive of 38 meters. From then on to 2012, "Jiaolong" won the sea trial of 1000 meters, 3000 meters, 5000 meters and 7000 meters. In June 2012, it successfully set a record for the maximum dive depth of 7062 meters of the same type of manned submersible in the Mariana Trench.

From June 5, 2013 to September 24, 2013, "Jiaolong" launched its first pilot application voyage, which achieved a complete success and marks the transformation of "Jiaolong" from sea trial stage to application stage.

Since the sea trial, "Jiaolong" successfully dived 158 times, taking 557 days in total, with a total voyage of more than 86,000 nautical miles, achieved 100% safe dives and obtained fruitful results in deep-sea scientific research. It has explored a number of seabeds " mining areas" in mountainous areas, cold spring areas, hydrothermal areas and mid-ocean ridges in several sea areas, helping scientists to obtain a large number of deep-sea biological samples, cobalt-rich crust samples, polymetallic nodule samples, rock samples, sediment samples, seawater samples, etc., and to have a preliminary exploration on typical seabed topographical areas such as seamounts, hydrothermal solutions and trenches.

Ocean University of China researches and customizes and participates in the design of "Dongfanghong 3", and many designs are" international initiatives".

On January 16, China's new-type far-reaching comprehensive scientific investigation ship for the sea, Dongfanghong 3, held a launching and naming ceremony at Shanghai Jiangnan Shipyard. This scientific research ship is customized and designed by Ocean University of China according to the precise research of marine science, and many indexes are leading the world.

"Dongfanghong 3" is a new generation of scientific investigation and practice ship developed independently in China. The ship is 103 meters long, 18 meters wide, with 110 personnel and a total laboratory area of 600 square meters. Equipped with the world's most advanced ship equipment and scientific research equipment, the ship can carry out high-precision comprehensive marine scientific investigation of the whole sea depth and space integration.

"Dongfanghong 3" is the third generation of ship type in the "Dongfanghong" series of scientific research projects initiated by the Ministry of Education in the past 60 years. Its construction marks that China's scientific investigation ships have already entered the ranks of world-class ship types. "Dongfanghong 3", with 103 meters in length, 18 meters in width, 5800 tons in displacement, 15 knots in maximum speed, 110 personnel, 15000 nautical miles of endurance, 60 days of self-sustaining capacity, unlimited navigation area, 600 square meters of scientific investigation working deck area and 600 square meters of laboratory area, is equipped with the world's most advanced ship equipment and scientific investigation equipment. The whole ship has been designed for vibration reduction, noise reduction and electromagnetic compatibility, and can carry out high-precision comprehensive scientific investigation of the whole sea depth and space integration. The integrated design of the core technical performance indicators, environmental parameter control and construction process in ship were first created in the world.

The short film "Top Ten Tourism Destinations in Shandong" at the promotion meeting made the participants both at home and abroad linger, and the Top Ten Tourism Destinations in Shandong went from here to the world!

" Top Ten Tourism Destinations in Shandong"

Eastern sanctuary, wonderland seacoast

Peaceful Mount Tai, City of springs Jinan

Former capital in Qi, canal with Shandong style

Water margin hometown, Yellow River seaward

Sincere Yimeng, prosperous Weifang